How To Avoid Destructive Tack-Welds

As a technical adviser to bench jewelers I often troubleshoot tack-, fusion- and pulse-arc-welding applications. One of the more frequently asked questions is related to what causes destructive tack-welds. Destructive tack-welds fail at temporarily welding the parts and often result in damage such as arcing, surface splatter, part deformation, excessive soot and permanent weld joints.

2 Minute Read

As a technical adviser to bench jewelers I often troubleshoot tack-, fusion- and pulse-arc-welding applications. One of the more frequently asked questions is related to what causes destructive tack-welds. Destructive tack-welds fail at temporarily welding the parts and often result in damage such as arcing, surface splatter, part deformation, excessive soot and permanent weld joints.

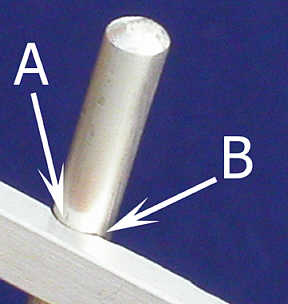

Destructive tack-welds are easy to avoid. Possible problems that lead to them are described in this summary. Oversized parts are being used to clearly visualize the examples.

Improper Joint Cleaning

When preparing a joint for tack-welding remove flashes of metal created by filing or grinding. Make sure the joint is clean and remove oil, soot or general debris.

These simple tack-welding rules apply to all joints regardless of the parts being tacked.

Important

Tack-, fusion- and pulse-arc equipment settings will differ and are based upon the volume, amount of contact and alloy of the material you are working with. Practicing using like materials will give you a parameter for the settings required for your application. Keep a record of settings and tasks for future reference.

You assume all responsibility and risk for the use of the safety resources available on or through this web page. The International Gem Society LLC does not assume any liability for the materials, information and opinions provided on, or available through, this web page. No advice or information provided by this website shall create any warranty. Reliance on such advice, information or the content of this web page is solely at your own risk, including without limitation any safety guidelines, resources or precautions, or any other information related to safety that may be available on or through this web page. The International Gem Society LLC disclaims any liability for injury, death or damages resulting from the use thereof.

The All-In-One Jewelry Making Solution At Your Fingertips

When you join the Ganoksin community, you get the tools you need to take your work to the next level.

Trusted Jewelry Making Information & Techniques

Sign up to receive the latest articles, techniques, and inspirations with our free newsletter.