Basic Principles for Wet Tumbling on Gold Jewellery

The correct use of modern, semi- automated finishing processes enables the manufacturer not only to reduce production costs, but also to improve the quality of finish on jewellery produced in series. This is the first of several articles, originally published in AURUM in 1982 on this important topic.

13 Minute Read

The correct use of modern, semi- automated finishing processes enables the manufacturer not only to reduce production costs, but also to improve the quality of finish on jewellery produced in series. This is the first of several articles, originally published in AURUM in 1982 on this important topic.

Introduction

The profitability of a jewellery manufacturing plant depends, among other things, on management's ability to control and reduce production costs. Since a major part of these costs arises from finishing operations such as deburring and cutting, and polishing or burnishing, most jewellery manufacturers in Europe and North America are increasingly taking advantage of the exciting opportunities offered to them by modern, semi-automated bulk finishing processes.

One of the most important of these processes is tumbling, and in this article we shall first take a look at the basic principles of the tumbling process and then show how it is applied in practice to the finishing of gold jewellery.

Often known as barrel polishing or tubbing in the jewellery trade, tumbling is in fact a very ancient process. It was used by the Egyptians in Antiquity, as well as by the Celts who place smooth pebbles and sand from the seashore into hollowed-out logs together with their iron weaponry, and then left this early example of a polishing barrel to roll in the sea for a few days.

In the more recent past, tumbling has been used mainly for burnishing findings and chain, which are difficult to polish by hand, During the past 20 years or so, however, this relatively unsophisticated operation has gradually evolved into a very effective and controllable finishing process which is widely employed today in many industries where mass produced small parts require a high quality finish.

In the jewellery industry, the tumbling process is used specifically for carrying out the following operations on jewellery parts:

- Deburring and/or cutting,

- Polishing or burnishing.

In the description of these processes that follows, specialized terms, such as "cut down", "media", "parts", etc., are employed. For the benefit of readers who are unfamiliar with this terminology, a short glossary is included at the end of this article.

| Figure 1 Barrel finishing. The operator is separating parts from media after the cutting cycle. |

Basic Principles of the Tumbling

Process

Tumbling is usually carried out in barrels that have a hexagonal cross- section. The parts to be processed are mixed with steel shot (for burnishing) or with appropriate abrasive ceramic or plastic chips selected from a variety of available shapes (for cutting). The steel shot and abrasive chips are known collectively as media. Various chemicals and abrasive powders mixed with water are also added to the load in the barrel. These materials are generally referred to as compounds.

By rotating the barrel horizontally around its long axis, the parts and the media are caused to rub against each other. The intensity of the resulting cutting or burnishing action on the parts depends mainly on:

- The speed of rotation of the barrel

- The diameter of the barrel

- The amount and nature of the media

- The amount of parts

- The amount of water

- The amount and type of compounds

- The cycle time (duration of the process).

Barrel speed

Figures 2a-c show how the speed of rotation (barrel speed) determines the way in which parts and media are caused to move in the barrel. For the purpose of illustrating this effect, the barrel in the photographs was half- filled with simulated media and parts (Figure 2a). This represents a filling ratio of 50 percent, which should be the minimum load to be used in practice. In Figure 2b, the barrel is rotating too fast, and its contents are being swept upwards only to fall back against the parts below. At such barrel speeds, the parts are not being cut down or burnished by the media, but are in danger of being severely damaged through colliding with one another. This phenomenon is known as impingement.

As the barrel speed is gradually reduced, the parts and media begin to move in a regular and orderly manner (Figure 2c), and effective cutting or burnishing action can take place. Note that there is a very little relative movement of media against parts within the bulk of the load or in the regions adjacent to the walls of the barrel. However, in and near the top layer of the load, there is a relatively narrow layer in which the components are constantly sliding and rolling downwards under the effect of gravity. It is only within this relatively narrow zone (the slide zone) that the desired cutting or burnishing action occurs (Figure 3).

| Figure 3 Diagram of rotating barrel showing the slide zone in which effective cutting or burnishing action takes place. There is relatively little movement in the bulk of the load. |

At this stage, any further reduction in barrel speed has the effect of decreasing the slope of the slide zone and hence the intensity of the action of media against parts. As a result, cycle times will be unnecessarily long. Only certain very special applications require very slow barrel speeds.

Hence, it is very important that the barrel speed should be correctly adjusted. If the speed is too slow, processing is inefficient and lengthy. On the other hand, if the speed is too fast for a given barrel and load, there is very little smooth contact between media and parts. The result is not only inefficient and uneven action, but the parts are likely to be damaged through impingement.

Filling Ratio and Load Ratio

The filling ratio is the volume taken up by the parts and media in relation to the total volume available inside a barrel. The photographs in Figures 4a and 4b, and the diagrams in Figure 5 illustrate the effect of filling ratio on the slide zone. For filling ratios lying between about 25 and 75 percent, the length and slope of the slide zone remain approximately constant. Nevertheless, at a ratio of 75 percent, there is substantially more material in the barrel and consequently longer cycle times would be required. Practical experience has shown that optimum action (working effect) of parts against media is generally obtained when the filling ratio lies between 50 and 60 percent.

The term load ratio is used to indicate the volume of parts in relation to the volume of media. If tumbling is carried out with insufficient media for a given amount of parts, the results will be unsatisfactory and, in addition, delicate items such as thin-walled hollow parts may be damaged through coming into direct contact with one another.

- a) 25% filling ratio.

- b) 75% filling ratio.

| Figure 4a-b The effect of filling ratio onthe slide zone in a barrel rotating at theoptimum speed. |

When calculating load ratios, remember that it is not the weights of the materials (media and parts), but the volumes that they occupy respectively in bulk which have to be taken into account.

Water Level and Compounds

Water is added to the barrel to a level just above the load. Too much water has the effect of cushioning the cutting or burnishing action in the slide zone, giving a very gentle, but slow action. Lowering the water level speeds up the process, but this tends to reduce the effectiveness of the compounds and give unsatisfactory results.

The purpose of adding compounds is to enhance the cutting or burnishing effect by keeping parts and media clean, to inhibit corrosion and to provide a cushioning film that protects the parts from damage. Compounds are of various types depending on the application involved and the results that are desired. For cut down, a compound is used that contains fine abrasive powders, as well as water softeners and emulsifying agents which keep the surfaces of the parts and media clean by removing fines (finelydivided abrasion products or smut).

Specially developed compound formulations are employed for restoring surface lustre after cut down (coloring) and for burnishing with steel shot. The systematic and carefully controlled use of high quality compounds is essential for obtaining the best possible finish on gold jewellery.

| Figure 5 Diagrams showing that the length of the slide zone in a rotating hexagonal barrel remains constant for filling ratios between 25% and 75%. |

Time Cycle

The processing time should, in principle, be kept as short as is necessary to obtain the desired results. Prolonging the time cycle beyond this point may lead progressively to a degradation of the finish. This is particularly so in the case of parts which have relatively sharp edges and corners. Similarly, the use of process parameters that result in excessively long cycle times should be avoided, for the longer the parts are allowed to churn around uselessly in the barrel, the greater the probability that they might be damaged by contact with the walls of the barrel and neighbouring parts.

Media

A variety of media is available for use in tumbling processes, ranging from ceramic and plastic chips in various shapes and sizes for cutting, to steel shot and needles for burnishing. Wooden chips and pegs are normally used only in dry finishing processes which will be discussed in a future article. A selection of available media is shown in Figure 6.

| Figure 6 A selection of media used in barrel finishing processes. Top left: plastic cones; Bottom left: ceramic chips; Centre: wood media; Right: steel balls, balcones and pins. |

Ceramic chips are seldom used in the wet tumbling process for finishing gold jewellery. Instead, the most universally popular and effective media are 12mm plastic cones (top left hand corner of the photograph in Figure 6). These moulded plastic media are made of polyester resins impregnated with fine abrasive powders and produce a fine, smooth cutting action particularly suited for finishing jewellery in gold and silver alloys.

The conical shape has the advantage that the media move smoothly and evenly over and between the parts. Plastic cones are also relatively long-lasting, for they become smaller and smaller in use without losing their original shape. Thus, by starting out with a batch of 12mm cones, one obtains smaller cones simply by using the original batch for a while. Small cones are useful for processing very small parts, so the media should be regularly passed through sizing screens and stored in batches according to size.

For burnishing, a popular and useful type of steel media consists of a mixture of round balls, pins and balconies ("ball cones").

Barrel Design

Today, most gold jewellery parts are processed in closed six-sided barrels rotating horizontally around their long axis. Open-ended barrels, which rotate around an inclined axis, are gradually falling into disfavour as manufacturers are discovering the many advantages and superior efficiency of the horizontal barrels.

In a horizontal barrel, the parts are in uniform motion over the entire area of the slide zone which extends throughout the length of the barrel. In an inclined barrel, however, cutting action is uneven and the slide zone smaller. Furthermore, when the difference in density between the parts and the media is fairly large - as is the case when metal parts are being processed with plastic media - some segmentation of parts and media tends to occur. This results in uneven and inefficient action.

Horizontal barrels usually have a hexagonal cross-section so that as the barrel rotates, the parts and media are carried upwards as far as possible and a steep slide zone is established. Round barrels have the disadvantage that the load tends to slip on the bottom so that an effective zone is not formed.

Barrel Materials

Tumbling barrels were mostly made of wood in the past. Today, barrels are generally made in special plastics that are very tough and have high impact strength. They are superior to barrels made from traditional materials because:

- Compared with wood, barrels made from such plastics last at least three to six times longer.

- Low carat gold or silver jewellery is sometimes found to be tarnished after processing in rubber-lined barrels. The cause has been traced to the effects of sulphur released from the vulcanized rubber during abrasive tumbling.

- Tumbling barrels of various shapes may be constructed fairly easily and to relatively high dimensional tolerances from modern plastics. Thus, the covers of access ports can be made to fit very tightly and the internal surfaces of the barrel are smooth. This eliminates the risk of possible damage to small parts if they are trapped in the crevices between cover and barrel.

- Plastic barrels can be washed and rinsed very effectively. This is of great importance in ensuring cleanliness, for in tumbling, exactly the same rule applies as in electroplating: the cleaner the equipment and solutions, the better the results that can be obtained. In the next part of this series, to be published in AURUM 10, we shall consider in some detail how the wet tumbling process is applied in practice for the bulk finishing of gold jewellery. Three distinct operations are generally involved:

- Cutting

- Coloring

- Burnishing.

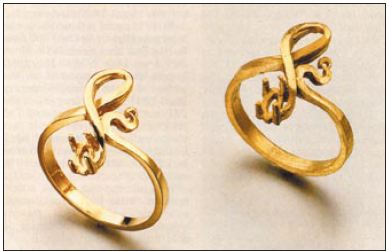

- There is, however, one very important preliminary step which must not be overlooked. Tumbling is not as selective as skilled hand finishing, and imperfections, such as parting lines and flash on castings, cannot be eliminated in the barrel, but must be removed by hand before the cutting cycle. The photograph in Figure 7 shows two signet rings. On the left is the raw casting which has very pronounced parting lines, flash and even beading resulting from air bubbles that were left behind when the original wax model was invested. The ring on the right has been "cleaned up" ready for cut down.

Glossary

- Balcones - Contraction of "ball cones", term used to describe steel media shaped like a ball on one end and a cone on the opposite end.

- Barrel speed - The speed of rotation of the barrel.

- Coloring - Term used in referring to the brightening of parts after the cut down cycle.

- Compound - A combination of chemicals, sometimes mixed with abrasive powders, that is added to the media and parts in bulk finishing operations to enhance the working action and protect parts and steel media from corrosion.

- Cutting - The first stage in the barrel finishing process during which the workpieces are smoothed down with abrasive media and/or compound.

- Cut down - A frequently used term for the cutting cycle in a barrel.

- Cycle time - The time required to process parts in a specific barrel finishing operation.

- Deburring - Operation to remove sharp edges and corners usually present on workpieces after stamping.

- Filling ratio - The ratio of the volume of media plus parts to the total internal volume of barrel. Expressed in percent.

- Fines - Very small, fine, particles that are worn off the media and parts during finishing operations.

- Impingement - Term used to describe the situation when parts come into direct contact with one another, or with media, in such a way as to cause damage to the parts, embedding of abrasives in the surface, or discoloration.

- Load ratio - Ratio of the volume of parts to the volume of parts plus media.

- Media - Material used in a barrel finishing process to perform work on the parts and separate the parts to prevent impingement.

- Parts - Workpieces, items of jewellery or other components, which are to be barrel finished.

- Tumbling -Term used to describe barrel finishing operations with rotating barrels.

| Figure 8 Before and after This photograph of two gold rings gives a good indication of what can be accomplished with modern tumbling processes. |

You assume all responsibility and risk for the use of the safety resources available on or through this web page. The International Gem Society LLC does not assume any liability for the materials, information and opinions provided on, or available through, this web page. No advice or information provided by this website shall create any warranty. Reliance on such advice, information or the content of this web page is solely at your own risk, including without limitation any safety guidelines, resources or precautions, or any other information related to safety that may be available on or through this web page. The International Gem Society LLC disclaims any liability for injury, death or damages resulting from the use thereof.

The All-In-One Jewelry Making Solution At Your Fingertips

When you join the Ganoksin community, you get the tools you need to take your work to the next level.

Trusted Jewelry Making Information & Techniques

Sign up to receive the latest articles, techniques, and inspirations with our free newsletter.