Basic Sawing Techniques

In this article, we will continue our Back to Basics Series with an article on Sawing techniques.

5 Minute Read

When legendary football coach Vince Lombardi took over the Green Bay Packers, he instituted training in the basics. At the first meeting with the players, he held a football up in his hand and said "Gentlemen this is a football." This was to a group of professional football players, who had played football most of their lives. If anybody knew what a football looked like, it was them. However, Coach Lombardi left nothing to chance. He knew the team that won was the team that performed the basics of football the best. The team that blocked better, ran the ball better, and tackled better than the other team, usually won. His Packers won the first two Super Bowls.

In all sports, professional athletes practice many of the same drills they learned in youth leagues as a child. They know practicing basic skills will allow them to perform better even at their level. Working on jewelry whether repairing or creating a new piece, is no different. A bench jeweler must perform basic skills with precision in order to create excellent work - Skills such a sawing, filing, soldering, and polishing need to be mastered.

In each issue of BENCH we will cover one of these skills in a series of articles titled Back to Basics. For the apprentice jeweler, these articles will lay the foundation upon which the skills of the trade can be built. For the rest, these articles will serve as an important review. At the jeweler's bench, even the most complicated task is a compilation of basic skills performed with precision and accuracy. Because of this it is advantages for all jewelers even the most advanced to review and practice the basics. This month we will cover the basic skill of sawing.

The jeweler's saw is one of the most widely used tools at the jeweler's bench. In the hands of a skilled craftsman, a saw can produce the most intricate patterns or accurate straight lines. It is also used as a file in small areas inaccessible by other tools. It is important for a bench jeweler to master the skill of sawing to perform quality workmanship. This skill is not difficult. However, to achieve precision practice of correct mechanics is required.

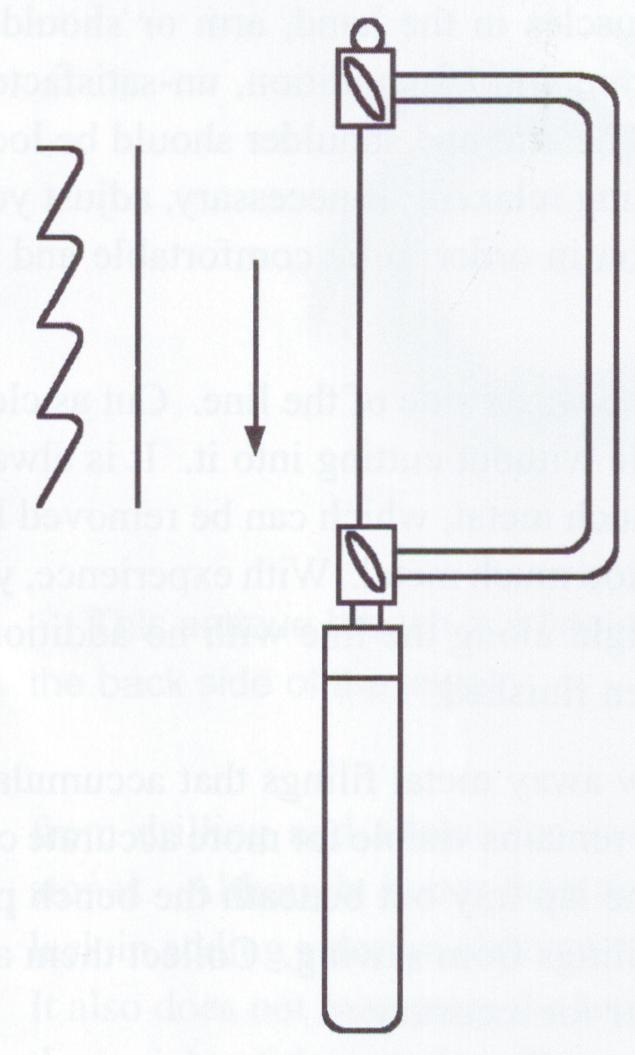

To begin cutting, place the metal on the bench pin. Hold it firmly; if the metal slips the blade will break. Rest the saw blade against the metal's edge and gently draw the blade downward. The blade should begin to cut. If it does not, check the blade. It maybe the wrong size for the metal being cut or it maybe installed upside down. The teeth should point down towards the handle, cutting on the down stroke. If the teeth point upwards, remove the blade and turn it around.

Select a blade size so that at least two teeth are in contact with the metal at all times.

Continue with a slow steady up and down rhythm using the entire length of the blade. This will allow you to saw faster and more accurately. Short choppy strokes result in uneven sawing and will prematurely wear out that section of the blade, causing it to break. On the downward stroke, a natural forward movement provides sufficient pressure on the blade. Too little pressure allows the teeth to simply scrape the metal, which is ineffective. An excess of forward or downward pressure will cause the blade to break.

Release the forward pressure on the upward return stroke. It only repositions the blade for the next downward cutting stroke. Excessive pressure while dragging the teeth on the up stroke can cause the blade to misshape and the teeth to wear unevenly.

Saw in front of your body in a forward direction. Some jewelers keep the saw in one forward position and move the metal into the saw. Others hold the metal steady and move the saw in the desired direction. Still others move both the metal and saw as necessary. With a little practice, you will develop the most natural method for you.

Sawing is most efficient when remaining relaxed while sawing. Tensing muscles in the hand, arm or shoulders cause fatigue and cramping. In addition, un-satisfactory sawing will result. The arm and shoulder should be loose and the hand remaining relaxed. If necessary, adjust your chair or body position in order to be comfortable and relaxed while sawing.

Always saw on the waste side of the line. Cut as close to the line as possible without cutting into it. It is always better to leave too much metal, which can be removed latter, than to cut away too much metal. With experience, you will be able to cut right along the line with no additional clean up needed when finished.

As you saw, blow away metal filings that accumulate. Then the cutting line remains visible for more accurate cutting. Always pull the lap tray out beneath the bench pin. This will catch the filings from sawing. Collect them and send them to a refiner for recovery.

Using a lubricant on the saw blade while sawing will help the blade cut through the metal smoothly and will help keep the metal particles from clogging the teeth. This reduces the chance of breaking the saw blade. To lubricate the saw blade run it through bees wax or a commercial product such as Bur Life before sawing.

Sawing a Straight Line

To saw a straight line, tilt the saw forward slightly. Then the cut already made will help guide the blade, and it is easier to sight the straight line along the blade.

Sawing Curves

To saw curves, keep the blade perpendicular to the metal. Tilting the saw forward while rounding a curve will pinch the blade causing it to break prematurely.

To make a sharp turn, continue the same up and down rhythm without any forward pressure. Then slowly rotate the metal around the moving blade. On each downward stroke, make a slight sideways cut until you reach the new direction.

Saw Maintenance

Saw blades do wear out. When teeth are dulled to the point where extra force must be used in cutting, it is best to replace the blade. Extra pressure decreases control; therefore nothing is gained by this economy.

Often saw blades break before they wear out, a wasteful situation. This can be avoided or at least minimized with proper sawing procedures. The two main reasons for blades breaking are too much force used while sawing, and pinching the blade from twisting either the metal or the saw frame.

DO NOT throw broken or worn out blades away. Particles of gold become lodged in the teeth during use. Place all old saw blades in the container with the used polishing machine filters to be refined. A good refiner can reclaim this gold.

Precise sawing is important. It saves both metal and time. When you perform accurate sawing very little, if any filing is needed. Following these basic procedures and with a little practice, one can easily master the art of using the jeweler's saw.

You assume all responsibility and risk for the use of the safety resources available on or through this web page. The International Gem Society LLC does not assume any liability for the materials, information and opinions provided on, or available through, this web page. No advice or information provided by this website shall create any warranty. Reliance on such advice, information or the content of this web page is solely at your own risk, including without limitation any safety guidelines, resources or precautions, or any other information related to safety that may be available on or through this web page. The International Gem Society LLC disclaims any liability for injury, death or damages resulting from the use thereof.

The All-In-One Jewelry Making Solution At Your Fingertips

When you join the Ganoksin community, you get the tools you need to take your work to the next level.

Trusted Jewelry Making Information & Techniques

Sign up to receive the latest articles, techniques, and inspirations with our free newsletter.