Bead Setting Method – Part 2

6 Minute Read

Now that we have done all the necessary preliminary "raising of beads" and "line-cutting" in the last issue, we are now ready to attempt the easier part of this technique called "bright-cutting"

Please, do not get discouraged if you do not find the results you are looking for, the first few times you perform this process. This particular "degree of skill" took me 4-5 years to learn, and you might get quite discouraged, in the beginning. So don't feel it's your fault, it's a very gradual learning curve.

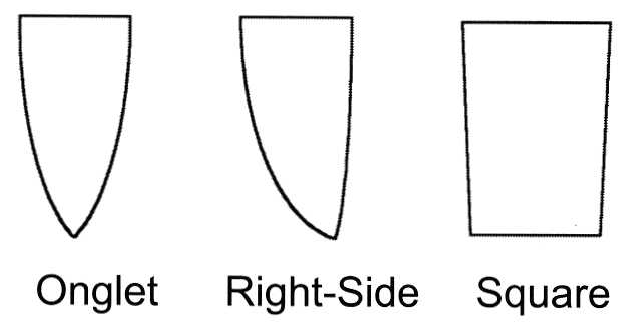

Let me start by stating that the "right-sided" graver is paramount in removing the metal from the wall of the line cutting you just finished. This tool will 'remove' and leave a highly polished wall that has a "slightly concave" angle. This "angle" will reflect more light than the flat wall created from a Flat Graver. The advantage of the Onglette #2 graver is that as you are cutting you leave a smooth line of cutting; with no visible faceting separation in between the "stop-start" cuts in the metal. So that if you put down your blade and start later, you won't see a difference of angles. If you maximize and take in your "hand leaning" angle, and get used to this particular cutting angle, you will find how your hand sits while holding the tool/graver. THIS IS ONE OF THE BASIC LAWS, the "hand-to-holding angle" Once you discover how you hold this tool, the rest is easy.

Why not use a Flat Graver? Glad you asked! There are many apparent problems with this graver.

- The graver must be held rather tightly, to have more control over the constant hand angle and maintaining a constant forward action!

- The side point of the flat graver ALWAYS 'hits' the stone being separated, hence re-sharpening even after two or three cuts in the metal. The front of the "flat cutting blade" and also at the bottom of this cutting blade is to be reshaped or honed at very frequents intervals. If the blade hits a hard piece of un-annealed gold, a piece of blade is actually broken off and the missing piece is shown on the wall of the metal being cut.

- The hand leaning angle must always be adhered to and the fullest concentration must be given at all times. You really don't need this aggravation.

I prefer a "right-sided" graver that has a wider cutting on the "right side" of the onglette graver. Prepare this highly polished "cutting blade" by hand polishing with multiple "emery and polishing" papers in a series of smooth well-defined hand strokes. Start with an emery paper of #1, and then progress to a finer paper #2. Wrap the polishing papers around a piece of wood, such as a paint stir, and then rest this piece of wood on the bench peg, this way you can get right up close to observe the polishing.

Use about 3/4 of the length of the paper with each side- to-side hand movement. Once this is done, examine the results, checking for any "scratches" in the metal. If there are any, redo this procedure. While sharpening, you must maintain the overall "concave-bevelled" angle that the graver was made with.

Polish the blade from the bottom of the knife-edge to the top of the cutting surface on the right side ONLY! When the blade is clean of marks, proceed to the next range of papers. "Polishing paper #210 then a finer #410. Use the same method of buffing using quick long strokes on the paper. Examining after every few seconds to make certain there are no marks left in the surface. Any marks in the leading edge of the graver will be transferred to the gold - so make certain you get them all out now!

Go to the last polishing paper and buff like heck and view your new blade. Do not apply heavy pressure on your cutting surface, gentle, definite constant pressure, must be applied. Finally, apply a bit of graphite from a pencil to one end of your #4/0 polishing paper and rub until you have a black surface on this paper. Now, very carefully rub your new graver quickly and lightly on this "black penciled section". The graphite will make yow #410 paper into a #610 grit, without buying this additional specialized paper. Once the tool is polished and all the marks are out, you will spend less time to maintaining it in the future.

You have just learned one of the hardest aspects of setting - preparing this very important tool. Maintenance of these specialized hand-made items are so very important. I always check my gravers before attempting a new setting job and never subject them to misuse.

We now have the tools shaped, gravers prepared, and comes the "fun" part, the actual procedure of rough-cut- ting.

If you are cutting row of diamonds, I would start just "after" the first bead. This way you will start a nice long line of "seamless cutting".

What should you look for and where to make the first cut? Have the rough-cutting gravers' point start right at the bead hole and scribe a fine line along the edge of where the diamonds are.

If you 'knock-off' some of the sides of the beads, do not worry. The beads are wide enough and thick enough for this to happen. We have made allowances just for this. For each and every line scribing you should dig deeper into the metal, until you reach a point that the girdle of the stone is now visible. Then stop and do the same to the other side of the stones. You should be "flicking out" the metal by lifting the ends of the graver at an upward angle. Cut each line just enough so that the graver won't get too deep into the metal. Cut a nice long line from the first "bead" to the very end of the row. Finish the cutting and then go back to clean up all the lines.

What about the spaces in between the diamonds? Make a small scribe again from inside of where the two beads are located and scribe a small square. Go over this cutting groove with your right-sided graver and make this square in to a small, angled bright "pyramid". As this will soon be polished, it will look like another diamond in between. Delicate and very clean looking is just what we are aiming for. All of these beads MUST be separated from the rest of the metal along the sides and again in between, near the "square".

Now that the lines are scribed, beads cleaned and other designs worked on, we can get out our bright-cutter. This is basically the same routine, very easy, just travel along the route you have just made. Have your gravers' point aimed at the base of the groove and the rest of the shiny part of the prepared blade will do the rest.

As you are trying to bright-cut, aim your gravers' point towards the edge of the girdle of the stone. This will give a clean affect as you cut. All through this procedure, get rid of as much of the remaining bits of metal that doesn't belong there. You should now have two rows of bright looking metal. When you have finished all of this cutting, obtain a bead burnisher, (you can buy these at your own tool supplier). Rotate your burnisher over the very tops of the beads. This will press down the bead on to the stone and slightly polish each and every bead you have just made.

There are two ways of finishing off the ends of the rows. I use either method, depending on the circumstances and the design. The easiest method is the one shown on top, it's very fast clean and only two minutes of extra work. Use your #1 Onglette graver and cut a "<" shape by aiming your tool towards the far end-corners of the metal, clean the metal around the beads and bright-cut. This job is now truly over and are now you all "mavens" in setting.

See Also:

Bead Setting Method - Part 1

Bead Setting Method - Part 3

You assume all responsibility and risk for the use of the safety resources available on or through this web page. The International Gem Society LLC does not assume any liability for the materials, information and opinions provided on, or available through, this web page. No advice or information provided by this website shall create any warranty. Reliance on such advice, information or the content of this web page is solely at your own risk, including without limitation any safety guidelines, resources or precautions, or any other information related to safety that may be available on or through this web page. The International Gem Society LLC disclaims any liability for injury, death or damages resulting from the use thereof.

Gerry Lewy

With over 40 years experience as a stone setter, Gerry Lewy is known throughout the diamond setting community. Gerry started his 9-year apprenticeship with a jewelry manufacturer and tutored by a gentleman ‘setter’, in Haddon Gardens, London. Gerry has redeveloped himself into more than a master setter, his purpose is now to be a teacher of the art as well.

The All-In-One Jewelry Making Solution At Your Fingertips

When you join the Ganoksin community, you get the tools you need to take your work to the next level.

Trusted Jewelry Making Information & Techniques

Sign up to receive the latest articles, techniques, and inspirations with our free newsletter.