Buffer System & Ultrasonic Basket Replacement

3 Minute Read

Buffer System & Ultrasonic Basket Replacement

Buy List

Handler 1250 CFM suction unit

Budget

When we replaced our vacuum tubes for the buffer system I chose to run PVC again. The PVC is easy to acquire and assemble and the smooth sides promote air flow. Most fittings are cemented but a few strategic points are just tight press fits to allow access in case items are sucked in.

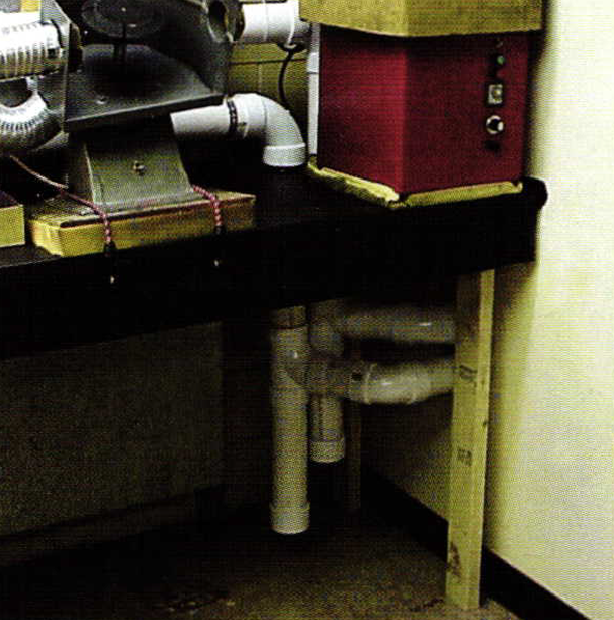

We are using a Handler 1250 CFM suction unit with 4 stations so each has at least 300 CFM well over the suggested minimum of 200 CFM. When installing the system I wanted to use only 45 deg. elbows to maintain flow speed.

A sharp 90 deg. bend and a vertical drop were used just prior to entering the filter area to catch large particles and help make the filters last longer. It also simplifies retrieving items accidentally sucked into the intakes. The two extensions below the T- couplings are just press fit and pull down for cleaning out.

We needed to solve the problem of small items being sucked into the exhaust system. All of our hoods were fitted bottom feed vacuum outlets. This allowed any stones or small parts to be thrown by the wheel to the back of the hood and sucked down the tube, which involved hours a month in disassembly to find items. I moved the vacuum outlets to the back of the hoods about 3 inches from the bottom and since installation not one item has been sucked in by accident.

This view shows the short piece of flex tube connecting the hoods to the PVC pipes. In case small items are thrown down and bounce up through the protective grate the tubing curves up to act as a trap and slow it down so it never makes it into the PVC pipes.

This is a simple 4 in. PVC snap-in drain. Remove the grate and place it on the back of the exhaust hood and trace around the inside diameter for a cutting template. After cutting the hole place the cover on the back and mark the cover screw holes and drill them. Now remove the screws, place the cover up to the cut hole from the outside, and screw through the hood into the pre tapped holes to attach the collar. Then you can attach your flex tubing.

You assume all responsibility and risk for the use of the safety resources available on or through this web page. The International Gem Society LLC does not assume any liability for the materials, information and opinions provided on, or available through, this web page. No advice or information provided by this website shall create any warranty. Reliance on such advice, information or the content of this web page is solely at your own risk, including without limitation any safety guidelines, resources or precautions, or any other information related to safety that may be available on or through this web page. The International Gem Society LLC disclaims any liability for injury, death or damages resulting from the use thereof.

The All-In-One Jewelry Making Solution At Your Fingertips

When you join the Ganoksin community, you get the tools you need to take your work to the next level.

Trusted Jewelry Making Information & Techniques

Sign up to receive the latest articles, techniques, and inspirations with our free newsletter.