The Foundation of Japanese Patinas

Niage is an important Japanese patina, and one of the most basic. It has been used as the base color on copper and copper alloys for centuries, and today it is also used as a final patina. As is true of all the recipes given here, these proportions are general guidelines, and experimentation is encouraged. A wide range of colors can be achieved by changing the concentration, proportions, or the time of exposure.

ISBN

5 Minute Read

Niage is an important Japanese patina, and one of the most basic. It has been used as the base color on copper and copper alloys for centuries, and today it is also used as a final patina. As is true of all the recipes given here, these proportions are general guidelines, and experimentation is encouraged. A wide range of colors can be achieved by changing the concentration, proportions, or the time of exposure.

Niage

- 3 grams rokusho Use commercial rokusho or the alternate recipe.

- 3 grams copper sulfate, CuSO4. 5H20

- 1 liter water

Grind the chemicals, one at a time, in a mortar and pestle until they are reduced to a fine powder. Heat the water, then stir in the copper sulfate until it is completely dissolved. Add the rokusho , again stirring until the powder has been completely absorbed. The copper sulfate takes longer to mix than the rokusho . Some people recommend adding a Japanese plum (umeboshi) to increase the red tones. It is best to heat the solution in a copper pot. If using glass, put a piece of copper in the vessel to supply additional copper to the solution.

Niage Process

- If possible, use a copper, stainless steel, or an enameled pot; this will insure that there are no compromising reactions with other metals. Heat the niage solution to just short of its boiling point and stir until the ingredients are blended. Note that some particles will remain undissolved, which is why it is important to stir the solution during the coloring process. Reduce heat to a simmer.

- Wash off the grated daikon with water. Do not touch the surface with bare hands. As before, the idea is to avoid contaminating the surface with finger oils. Wear clean rubber gloves.

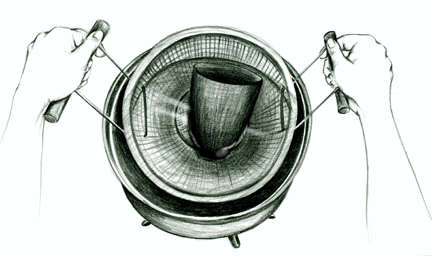

- Place the work in a plastic strainer. If a plastic strainer is not available, or is the wrong size for your needs, make a wire structure that is appropriate for the work and line it with a cloth. This will cushion the work and prevent scratches.

- Immerse the work into the heated solution. To insure an even color, turn the object periodically with plastic or wooden tongs. Because the chemicals can settle out of solution, stir the mixture periodically.

- Continue until the desired color is achieved-the longer the heating time, the darker the color. If you allow the process to continue a long time, remember to add water to compensate for evaporation.

- When the chosen color is achieved, remove the work from the solution, rinse it under running water, then dry it with a clean, oil-free cloth.

| Immersing work in niage solution |

The finished color will depend on the duration of immersion, the proportions of ingredients, the temperature of the solution, the thickness of the metal, and whether the solution is applied to cast or chased work. In general, niage produces this sequence of colors, in which high-copper alloys (e.g., bronze) tend to fall toward the right-hand end of the scale:

Straw yellow > Gray-brown > Rust > Brick-red > Liver-colored > Dark brown

Niage on Copper

Use the recipe on the preceeding page to create a gray-brown, bronze-like patina on copper. To achieve a darker brown, make a more concentrated solution by using 15 grams each of copper sulfate and rokusho. [See Samples]

Niage on Brass

When brass objects are heated in niage solution at a low temperature the resulting patina will be pale green. If heated to a high temperature, the color will be ochre. [See Samples]

Niage on Shibu-ichi

The niage solution will turn shibu-ichi light gray to dark gray. To make the color darker, add a small amount of shaku-do to the alloy. [See Samples]

To achieve other colors on shibu-ichi, it is first necessary to bring the silver to the surface. This is done by heating the finished piece in a soft flame, just to the point where it oxidizes, then immersing it in pickle . Repeat several times and you will see the work take on the appearance of silver. This layer does not respond well to patina chemicals, and can be selectively abraded away with sandpaper or pumice to achieve a feathered edge between colors. Heat the work in a niage solution to a temperature of about 50-60° C (122-140° F). The alloy will take on a reddish color, and when left in the simmering solution for a longer time, the color will change to a lovely gray. During the process, the surface will reveal a beautiful crystal structure, a peculiarity of this popular alloy.

Niage on Kuromi-do

To create a matte black patina, immerse the work in a warm niage solution. During this process, it is likely that a random pattern of red dots will appear. To color over these, dilute the solution and boil the work for a while longer until the surface achieves a uniform black color. There are reports of metalsmiths pickling their work in a strong sulfuric acid bath immediately before using the niage solution on kuromi-do. [See Samples]

Safety Note: This solution is safe to touch, but you should wash your hands thoroughly when the work is done. The vapor is also safe because only the water evaporates, not the chemicals.

Su-tanpan

Su-tanpan is another traditional patina that is normally used as a base upon which other patinas are applied, but it can also be used as a patina color all by itself. The results can range from light brown to gray to dark brown, depending on the strength of the solution and the length of time the solution is in contact with the metal. [See Samples]

Su-tanpan Recipe

- 40 grams copper sulfate, CuSO4 . 5H20

- 10 grams table salt (sodium chloride), NaCl

- 1 liter vinegar

Grind the copper sulfate and salt in a mortar and pestle to create a fine powder. Mix these powders together well, then gradually add the vinegar. Pour into a glass or plastic container, mark it with the name, ingredients, and the date it was mixed.

Su-tanpan Process

- Prepare the metal as described earlier-finish all metalwork, polish with charcoal or fine abrasive papers, and degrease.

- Apply a coating of grated daikon radish and leave this in place until you are ready to apply the patina. The radish should be on the metal for at least several minutes.

- Apply the solution to the cleaned metal object with a broad paintbrush. In Japan we use a calligraphy brush.

- When a uniform and attractive color has been achieved, rinse the piece with water and let it air dry.

Another Use

Su-tanpan is most often described as a base for copper, but it also creates a dark gray patina on silver. Use the recipe given above, and immerse the work until a uniform color appears. In most cases, the patina is polished off raised areas to create contrast between the light colored metal and the darkened recesses. In Japan this is traditionally done with baking powder. Other solutions used in Japan to darken silver include tincture of iodine and a sulfur-based product called muto-happu.

| Apply the solution by immersion or with a brush |

You assume all responsibility and risk for the use of the safety resources available on or through this web page. The International Gem Society LLC does not assume any liability for the materials, information and opinions provided on, or available through, this web page. No advice or information provided by this website shall create any warranty. Reliance on such advice, information or the content of this web page is solely at your own risk, including without limitation any safety guidelines, resources or precautions, or any other information related to safety that may be available on or through this web page. The International Gem Society LLC disclaims any liability for injury, death or damages resulting from the use thereof.

The All-In-One Jewelry Making Solution At Your Fingertips

When you join the Ganoksin community, you get the tools you need to take your work to the next level.

Trusted Jewelry Making Information & Techniques

Sign up to receive the latest articles, techniques, and inspirations with our free newsletter.