Heimerle + Meule: Innovation as a Factor for Success

14 Minute Read

The market always has new ideas and strategies for its customers that companies geared towards technology need because they mean growth and real net value. However, innovations don't spell success unless the market accepts them because they boost customer benefit. What's especially important is products being closely interlinked to the customers' needs and that's where companies with interesting ideas have to score with purchasers in economically difficult times. Indeed, companies and service suppliers can only fill the market's needs by constantly coming up with new ideas. The workplace in the jewelry industry or crafts and the jeweler's or goldsmith's presentation of goods for sale is not only a practical matter. It offers the user reliability and convenience. The bottom line is: customers are not only looking for the latest gadget, but shapes and designs have to be state-of-the-art.

The ideal way to reclaim precious metal

The Pforzheim-based gold and silver separating shop Heimerle + Meule is a service company featuring separating, scratching and gold bath processing and applications. Their highly qualified employees have state-of-the-art measuring and testing equipment on hand for analyses and material and metallographic tests. Something new presented by Heimerle+Meule at the Inhorgenta show in Munich is a built-in system for reclaiming precious metal for high and low solution concentrations combining electrolysis and ion exchange. The system consists of an Auroclaim 30 and the IAT 20, both components that can be switched one after another, to deliver significantly better results than in a conventional separate application. The marketing manager Heribert Hillbrecht explains that "Auroclaim 30 has high separation rates with its electrolysis while ion exchange bonds the precious metals staying in the solution with its novel IAT 20. When this system was rolled out on the market, it indicated to us that we wanted to move forward with designing our instruments and equipment."

The improvement in Auroclaim 30 in comparison to its predecessor model Auroclaim 20 is the fact that the cell was enhanced for enhanced flow guidance. Now, we can separate as much as 1,500 g of gold in the cell. Another innovation is installing a self-priming circulation pump that can be used for swells, used galvanic baths and stripper solutions with medium and high concentrations of precious metals. The IAT 20 plant shows its stuff with low to medium concentrations of precious metals in the form of cyanide or chloro- or sulphato-complexes.

But the real innovation in this ion exchange is the way it is handled. You no longer have to spend a lot of time filling and removing the loose resin. You only have to exchange the bags with the special resin that Heimerle + Meule provides. When they are enriched with precious metals, Heimerle + Meule takes them back and gives you the precious metals extracted along with new empty bags. The special resin in the bag was specifically enhanced for precious metals meaning it can take on especially large loads. They can supply bags for reclaiming gold, silver; platinum, palladium, rhodium, ruthenium and iridium. Heribert Hilbrecht says "both machines can be operated as stand-alone equipment or in series for higher profitability. The major improvements in technology and easy exchange of foam cathodes and resin bags give all customers the choice of low investment or operating costs." • Heimerle + Meule www.heimerle-meule.com

Casting facility at bench site

With the introduction of the compact centrifugal casting device Cast by Ti- Research casting is possible even in small shops. Casting of unique CAD/CAM designs or small series is done within a working day or less. The unit allows casting of approx. 250g of gold, silver, platinum or other alloys in one working cycle. Due to the patented casting principle the dimensions of the device could be reduced to 44 size. The new principle allows casting into the rotating mold saving up to 50% of waste metal by avoiding the main stem known from conventional tree structures. Ti-Research also offers a tailor made product range of investments for satisfactory casting results with all metals. For metals with high melting point in particular the fast setting investment Invest C/P reduces the working cycle from spruing to devesting down to two hours without loss of accuracy. • Ti-Research www.ti-research.com

LED daylight for showcases

System Eickhorst came up with the daylight LED as a new illumination idea for presenting jewels and jewelry. LED's, otherwise known as light emitting diodes, make it possible to show natural daylight. The newly developed LED Expolite provides brilliant natural LED daylight in showcases. This gives jewelry and watches explosive colors, reflexes and intensive fire while making your assortment of jewelry more radiant and catching the customer's eye. Now you can brightly replicate brilliant colors in showcases and showrooms that are only visible in sunlight with a color temperament of 5,800° Kelvin. In contrast to conventional halogen lamp lighting, LED daylight only radiates a little bit of heat, which is of enormous benefit in showcases and shop windows. Not only that, it only requires a fraction of the power. Light emitting diodes have an extremely long service life of 20 to 30 years while only reducing luminous power a little. More than 80 daylight emitting diodes radiate along a length of 30 cm and that much more with other standard lengths ranging up to 120 cm. Special designs create a first-class presentation in highly sturdy showcases. The hallmark of this innovative aluminum section lighting technology is dissipating a low level of heat, a long service life and excellent color reproduction unobtrusively installed. • Heuer www.eickhorst.com

Elmamotion - perfection in motion

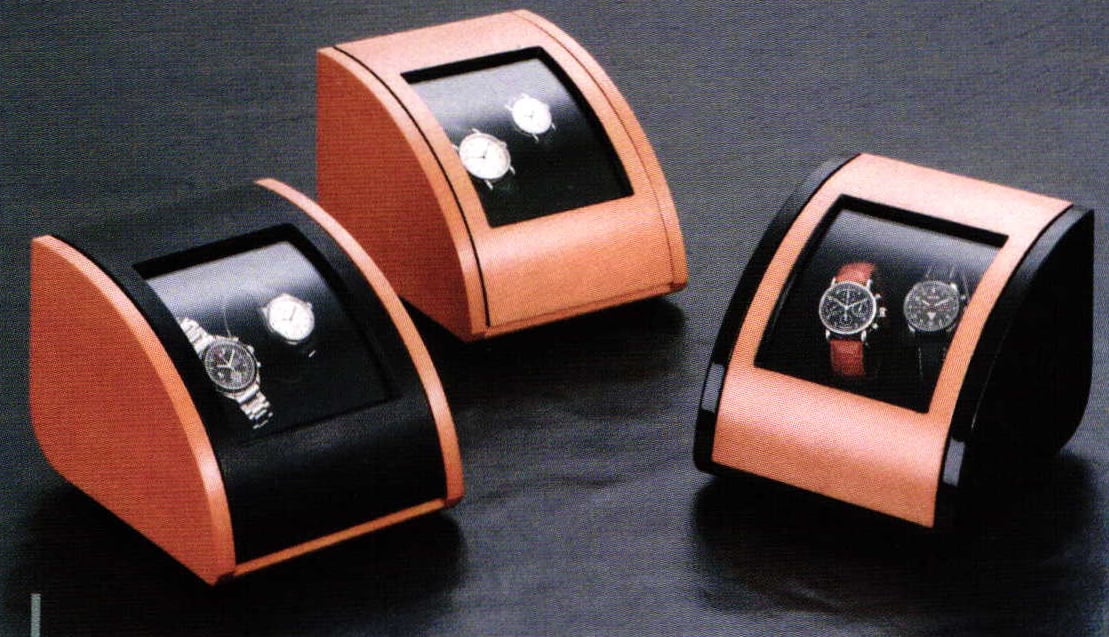

Elma has been producing quality products focusing on ultrasound cleaning technology for more than 50 years, including a wide range of special mechanisms developed, produced and sold for the watch and jewelry service. Now, Elma is showcasing a new generation of the clock movements they came up with 40 years ago under the name Elmamotion in a new and exclusive design. The hallmark of the Elmamotion clock movement is innovative engineering, reliability and high-quality hand work. These mechanisms have a solid and heavyweight quality making them extremely sturdy. A combination of high-quality materials such as pear tree wood, black piano lacquer and leather make these clock movements an exclusive and decorative accessory in the jeweler's sales spaces. The watches can be easily inserted and removed with the wide open swing-top box lined with black non-sensitive velour to protect these precious collectors' items. The lower side is covered with soft felt to prevent any scratches.

Especially for watches with the moon's phases and an eternal calendar, these clock movements make a lot of sense since they can be stored for a longer period of time without stopping. The mechanism automatically turns on every half an hour for six minutes and runs alternately in the left or right direction to wind watches with rotors winding in both directions. Then the mechanism automatically starts a new interval changing the rotational motion, which is beneficial for watches that only wind to the left or right. The winding types are either cyclical or permanent. Elmamotion works in cyclical mode at intervals of 6 minutes of winding time alternating with interruptions of 30 minutes. It works in permanent mode when the watch is run down, and its mechanism can switch over to cyclical mode after one hour running in permanent mode. This winding duration covers all known watch models, meaning that watches with the moon's phases don't have to be rewound. The changing direction of rotation makes it possible to wind automatic watches with left- or right-running function.

The clips are removable and match almost every watch model while they slip easily on the strap. Ball-bearing gear motors that are especially quiet are used for the drive mechanism. Finally, the Elmamotion clock movement has long malfunction-free service life and low power consumption. • Heuer www.elma-ultrasonic.com

Expert advice and a sophisticated assortment

Birkenstock & Co., mainly called "Beco-Technic" within the industry, has been known as a TOP supplier of watch and jewelry technology for more than 50 years, at home and abroad. Experience and know-how make the company a well-qualified contact in the high-tech testing equipment sector for machinery and tools as well as spare parts for the day-to-day watch and jewelry service. With the help of optimal logistics, all current products, such as machinery, equipment, cleaning fluids, batteries, ear studs, watch straps, substitute works, semi-finished jewelry products, watch spare parts and accessories can promptly be delivered. Additionally, the company offers the whole range of high technologies for professional handicraft in service centers and industries such as spot welding machines and polishing units as well as ergonomical workplaces "made in Germany". • Birkenstock www.beco-technic.com

There's no substitute for quality

Since Busch was set up in 1905, quality has been their middle name. It is almost 100 years old, making it one of the oldest and most reputable manufacturers of rotating tools. It has a history of successful entrepreneurship combined with a fine feeling for modernity and innovation. They export the tools they produce in their Engelskirchen-based facility into 80 countries all around the world drawing on their knowledge of the needs of the national and international market. Its extensive range of products encompasses tools made of steel, hard metal and diamond and polishers for precious and non-precious metals and abrasive wheels.

Busch's new catalog with its expanded range of rotating tools has been available since May of this year including some of its latest innovations, such as the new Clean Cut Cup Bur 411CCC with a cross recession for rounding off chaton settings. Rounding off claws or also prongs when setting precious stones calls for precision tailor-made tools. Even with the excellent cutting geometry of these tools, chips may get backed up and clog the tool. To counter this effect, Busch has come up with the CCC bur hollow drill (CCC means clean cut cup bur). The special thing about the CCC bur is not only the specially developed cutting geometry of the precision cross recession that promotes chip transport for enhancing the cutting performance. It also prevents the tool from getting clogged. The CCC bur made of tool steel is available in 10 different sizes or as a set.

The circular drill is an indispensable standard tool for doing drilling work on all gold alloys. A very high-quality cutting geometry adapted to the various ISO sizes spells out precision working. An example of the classical applications of a circular drill is setting up holes for case sets. Busch now supplies this drill in 44 different ISO sizes ranging from 003 to 085 (including sets) to give users more flexibility at work.

Finally, another innovation is the 203HM hard metal spiral drill for matching holes in hard materials difficult to machine. Its range of diamond cutters is now available in five granulations and they expanded the range of polishers and created user-friendly tool sets. • Busch mail@busch-co.de

The Japanese "Mokume Gane" technique for users

Since the onset of this year; Schichtwerk has added manufacturing high-quality and durability galvanized layered material to its portfolio. "Mokume Gane" is produced by welding thin sheets of a variety of nonferrous heavy and precious metals and their alloys with contrasting colors. Welding is done without flowing agents or solder so that this process requires metals with metallurgic and processing qualities. The blocks of layered metal forged in this fashion are treated with hallmarking, milling, engraving or etching techniques, although torsioning, forging and rolling techniques also leave an imprint on metal layers. Etching and oxidation put the finishing touches on this process.

The visual impression left on the surface structure is similar to that of a fine wood graining. That's why the name of the process is translated from the Japanese "Mokume", which means wood graining while gane equals metal. Gold- and silversmiths who already have experience with galvanizing precious metals are aware of how difficult it is to prepare layered material. Unwanted melting processes or metal blocks that are difficult to machine, separate and delaminate completely after first contact with the goldsmith's roller are well-known problems. The Americans Hiroko Sato and Gene Pijanowski familiarized themselves with classical "Mokume Gane" in Japan in the 70's, brought this technique to the United States and were the first to use them in jewelry. The Japanese sword smith Denbei Shoami (1651-1728) went down in history as the first to discover "Mokume Gane" of non-ferrous metals originally conceived for decorating precious Samurai swords. Its major uses were with hand guards, known as the tsuba, that increasingly emerged as a work of art and status symbol.

The layered work encompasses a wide range of materials such as copper / silver palladium / silver yellow gold / silver all the way to ternary alloys made of palladium, yellow gold and silver.

Layered metals containing the traditional Japanese "Mokume Gane" alloys such as "shakudo" (Cu with 4% Au) and "shibuichi" (Cu with 15% Ag) are being prepared, although they are experimenting with bronze and iron. The charm of alloys with copper is in the various oxidations and patina techniques that lend the surface of the finished objects a hitherto unknown appearance. The semi-finished products generally consist of fifteen layered metals each measuring 0.5 mm, although other thicknesses can be compiled as desired. * Schichtwerk www.schichtwerk.comwww.schmuck-schmiede.ch

Experienced, seasoned and radiant

Chris Jentner is an expert in surface and electroplating for 30 years and he has been tackling the development, manufacture and sales of electrolytic electroplating baths and chemicals, galvanizing equipment and systems to meet the surface refining demands of the Pforzheim and international jewelry industry for high-quality and easy-to-operate galvanic baths for color gold-plating, gold-plating, burnish silver-plating and rhodinating. It is a standard operating procedure for a company so experienced in galvanic baths and systems to impart this knowledge to its customers in terms of engineering, manufacturing and installing galvanic systems. They also offer customer training in their systems and they teach the how-to-work with electrolytes. Chris Jentner makes his specialists available to the customers including an analysis laboratory with state-of-the-art equipment for all of their problems.

One of the areas where Chris Jentner has invested a great deal of money in the last few years is services and environmental protection for a contract electroplating shop in metal refining. That's what company owner Chris Jentner means when he asks "what would make more sense than using our own chemicals in our systems? That's why we decided to expand our customer service 3 years ago and launch our own contract electroplating shop allowing us to constantly check and develop the quality of our bath chemicals". Since then, the well equipped contract electroplating shop is among the leading electroplating shops in the region. Refining jewelry products, watches, glasses, coins, cutlery or other decorative accessories is everyday business. They are also featuring services for technical and medical products. This also includes contacts and surgical instruments. They make several manual electroplating systems, and two process-controlled automatic electroplating plants are available to their customers for metal processing including all the common electroplating baths such as gold, silver, rhodium, palladium and platinum. Environmental protection has become the most important product. Jentner only uses what is known as "rainbow current" from renewable sources. All of the sewage water from the electroplating shops are cleaned state-of-the-art and in the cycle. Nothing is discharged into the sewage water and the residues are used as raw materials after processing. Jentner goes on record with his statement that "waste heat utilization is the next topic. After all, galvanic processes for surface refinement of metals require major quantities of heat. We will also utilize this residual heat".

Jentner's chemicals, baths and systems are being used all over the world these days. Since they have a burgeoning foreign business, they are called upon to maintain a high profile at foreign fairs in places like Bombay, Bangkok and Hong Kong. They serve some of their customers in India, Thailand and Hong Kong, China directly and some through dealers. Jentner's products and services are presented at national fairs, "Surfacts" in Karlsruhe, "Turntec" in Frankfurt and "Galvanica" in Stuttgart, Germany, and "Baselworld" in Switzerland. • Jentner www.jentner.de

by GZ Art+Design

You assume all responsibility and risk for the use of the safety resources available on or through this web page. The International Gem Society LLC does not assume any liability for the materials, information and opinions provided on, or available through, this web page. No advice or information provided by this website shall create any warranty. Reliance on such advice, information or the content of this web page is solely at your own risk, including without limitation any safety guidelines, resources or precautions, or any other information related to safety that may be available on or through this web page. The International Gem Society LLC disclaims any liability for injury, death or damages resulting from the use thereof.

The All-In-One Jewelry Making Solution At Your Fingertips

When you join the Ganoksin community, you get the tools you need to take your work to the next level.

Trusted Jewelry Making Information & Techniques

Sign up to receive the latest articles, techniques, and inspirations with our free newsletter.