Platinum Jewelry Advanced Joining Techniques

Joining is a very important production technique in the field of jewelry production. Therefore it is useful to know, what kinds of different joining techniques are possible. This paper will give you a rough overlook on joining techniques as well as some tips and tricks to do a good joint between platinum and platinum, and between platinum and gold. Which technique to prefer depends on the worker skill and on the available equipment.

5 Minute Read

Joining is a very important production technique in the field of jewellery production. Therefore it is useful to know what kinds of different joining techniques are possible.

This paper will give you a rough overlook on joining techniques as well as some tips and tricks to do a good joint between platinum and platinum, and between platinum and gold. Which technique to prefer depends on the worker skill and on the available equipment.

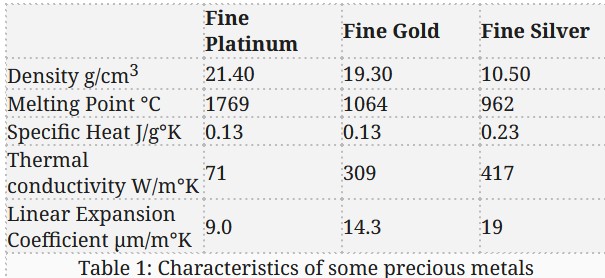

Usually the joining techniques for platinum jewellery are similar to the procedures used for gold and other materials. There is no black magic, only some material properties are different. If you know how it works, it is easy to do a good platinum joint. Some characteristics of some precious metals are shown in Table 1.

| Fine Platinum | Fine Gold | Fine Silver | |

| Density g/cm3 | 21.40 | 19.30 | 10.50 |

| Melting Point °C | 1769 | 1064 | 962 |

| Specific Heat J/g°K | 0.13 | 0.13 | 0.23 |

| Thermal conductivity W/m°K | 71 | 309 | 417 |

| Linear Expansion Coefficient µm/m°K | 9.0 | 14.3 | 19 |

| Table 1: Characteristics of some precious metals | |||

The biggest differences between the precious metals gold and platinum are the thermal conductivity and the expansion coefficient. You will see the results, if you bond platinum and gold together.

Example: if we solder together two 10mm long pieces, 8ct gold with Pt 950, using a gold solder with a work temperature of 750°C, the platinum expands 0.07 mm and the gold expands 0.106 mm. When the soldered material cools down to room temperature, there will be a lot of residual stress inside it.

Joining Techniques

1. Soldering

Advantages:

- You can choose different possible soldering techniques. Soldering by torch, in a furnace or by induction with a generator. Torch-soldering is the most common method for benchworkers. Furnace and induction soldering are more used for mass production and industrial manufacturing.

- Soldering by torch is a simple goldsmith technique, every benchworker can do it easily in each workshop, without use of expensive equipment.

- All combinations of alloys and shapes can be done.

Disadvantages:

- Very often you get a visible colour change in the solder seam. There is no solder alloy available which has the same colour as the alloys to be soldered.

- Soldering is not a controlled process, so we get often porous seams. Pores are visible and give us many plating problems.

- Solder alloys often contain zinc and/or cadmium. Therefore the seam is subject to corrosion and/or oxidation.

- Usually we have to plate the jewellery items because of the colour change.

- The solder seam has different properties regarding wear resistance. In practice we see that the solder seams polish out very easily.

Tips and Tricks:

- The jewellery items should be pre-polished before soldering and the joint surfaces should be rough, to increase the strength of the joint.

- Fit the parts as closely as possible (Preferred gap: 0.2 mm).

- Keep the joint and nearby areas clean.

- Use a precise oxidising flame (Hydrogen/oxygen preferred).

- To create a strong bond, use the hardest solder (Prefer platinum containing solders or use palladium-white gold).

- To increase the strength of the bond between platinum and gold, first flush the platinum surface with a hard solder, then use a soft solder for the second soldering operation.

- First solder the gold, then heat up platinum.

- For platinum/gold joints use a flux to remove the oxidation from the gold part (Cehaflux, Platiclean).

- For platinum/platinum joints flux is not required.

2. Puddeling

Advantages:

- It is a simple goldsmith technique, that does not require expensive equipment.

- It can be done in any workshop.

- You get jewellery pieces without visible seams.

Disadvantages:

- Not all shapes can be obtained. Only partially drilled or burred areas can be filled with gold.

- Gold melts at lower temperature than platinum, so it is not possible to fill gold jewellery with platinum.

Tips and Tricks:

- To increase the strength, it would be helpful to prepare undercuts in partially drilled areas.

- To fill fine gold in platinum, you do not need flux. To fill carat gold in platinum, flux is recommended (Cehaflux, Platiclean).

- Work carefully, heat up small areas to control the metal flow.

- If you fill the drilled areas with melt, they will sink after solidification. You overcome this problem if you build up material over the drilled areas, and file them down.

3. Bi-Metal Casting

Advantages:

- In general small and large parts with any desired shape are possible.

- There is no need for plating the seam.

- Easy to do with platinum.

- With this technique we can insert small platinum sections in coloured gold jewellery.

Disadvantages:

- This joining technique is useful only for the combination of platinum with other metals. No sense for joining platinum to platinum.

- This technique requires effort.

- Casting know-how is required, because bi-metal casting is a complex technique, only for skilled casters.

- The burnout cycle in the casting process increases the grain size of platinum. Tips and Tricks:

- Platinum should be pre-polished before casting.

- Prepare the metal/wax patterns with an overlapping of wax. Be sure that there is no gap between wax and metal.

- Surfaces to be joined should be rough, to give additional strength to the joint.

- Use a short burnout cycle (prefer high-speed investment).

- Use a low flask temperature, and a high casting temperature.

- Cool the flask down slowly under 100°C before quenching.

- Remove the investment carefully (don't use hammer).

- After investment removal, do a short annealing to relieve residual stresses.

4. Sintering

Advantages:

- All alloy combinations are possible, in any desired shape.

Disadvantages:

- Time intensive preparation of the precise parts is needed.

- Expensive equipment is required.

- Strength is lower, in comparison to other joining techniques.

Tips and Tricks:

- Prepare the parts precisely, to get a good surface contact.

- Surface roughness should be lower than Ra=1.6 µm, but the surface should not be highly polished.

- To get a strong bond, a thin layer of reddish gold will increase the diffusion rate.

- Before sintering, flush three or four times with protection gas (Argon).

- Use a sintering temperature 50°C under the solidus of the lowest melting alloy.

- Don't use a carbon mould for platinum.

5. Welding

Advantages:

- No visible seam, when joining platinum with platinum.

- No plating required.

- Joining small and large parts is possible.

- Highest strength of all joining techniques.

- Different welding techniques are possible, like torch-, arc-, laser-welding, etc.

Disadvantages:

- Not all alloy combinations can be used.

- For laser welding you have to invest in expensive machines.

Tips and Tricks for Torch Welding:

- Prefer a hydrogen/oxygen flame.

- Use a filler of the same alloy in the joint.

- The filler should bulge about 0.5-1 mm out of the seam.

- To get a strong bond, melt the filler as well as the platinum pieces.

- Platinum and filler material have to melt at the same time.

- For long welding seams, move the flame constantly in the same direction.

Tips and Tricks for Laser Welding:

- Use a high welding power to get deep into the metal.

- Use a filler wire of the same alloy.

- Fill up the welding seam with wire.

- To get a crack and stress free seam do a minimum 80% overlapping of the laser spots.

- Don't laser different metals together, you will create a "new alloy".

You assume all responsibility and risk for the use of the safety resources available on or through this web page. The International Gem Society LLC does not assume any liability for the materials, information and opinions provided on, or available through, this web page. No advice or information provided by this website shall create any warranty. Reliance on such advice, information or the content of this web page is solely at your own risk, including without limitation any safety guidelines, resources or precautions, or any other information related to safety that may be available on or through this web page. The International Gem Society LLC disclaims any liability for injury, death or damages resulting from the use thereof.

The All-In-One Jewelry Making Solution At Your Fingertips

When you join the Ganoksin community, you get the tools you need to take your work to the next level.

Trusted Jewelry Making Information & Techniques

Sign up to receive the latest articles, techniques, and inspirations with our free newsletter.