How to Quickly Dome Irregular Forms

2 Minute Read

With this procedure you can dome nearly all regular or irregular shapes or forms, as long as the edges or the corners of the form are not too tight. The procedure worked well with copper sheet up to 5 mm and fine silver sheet up to 8 mm thickness.

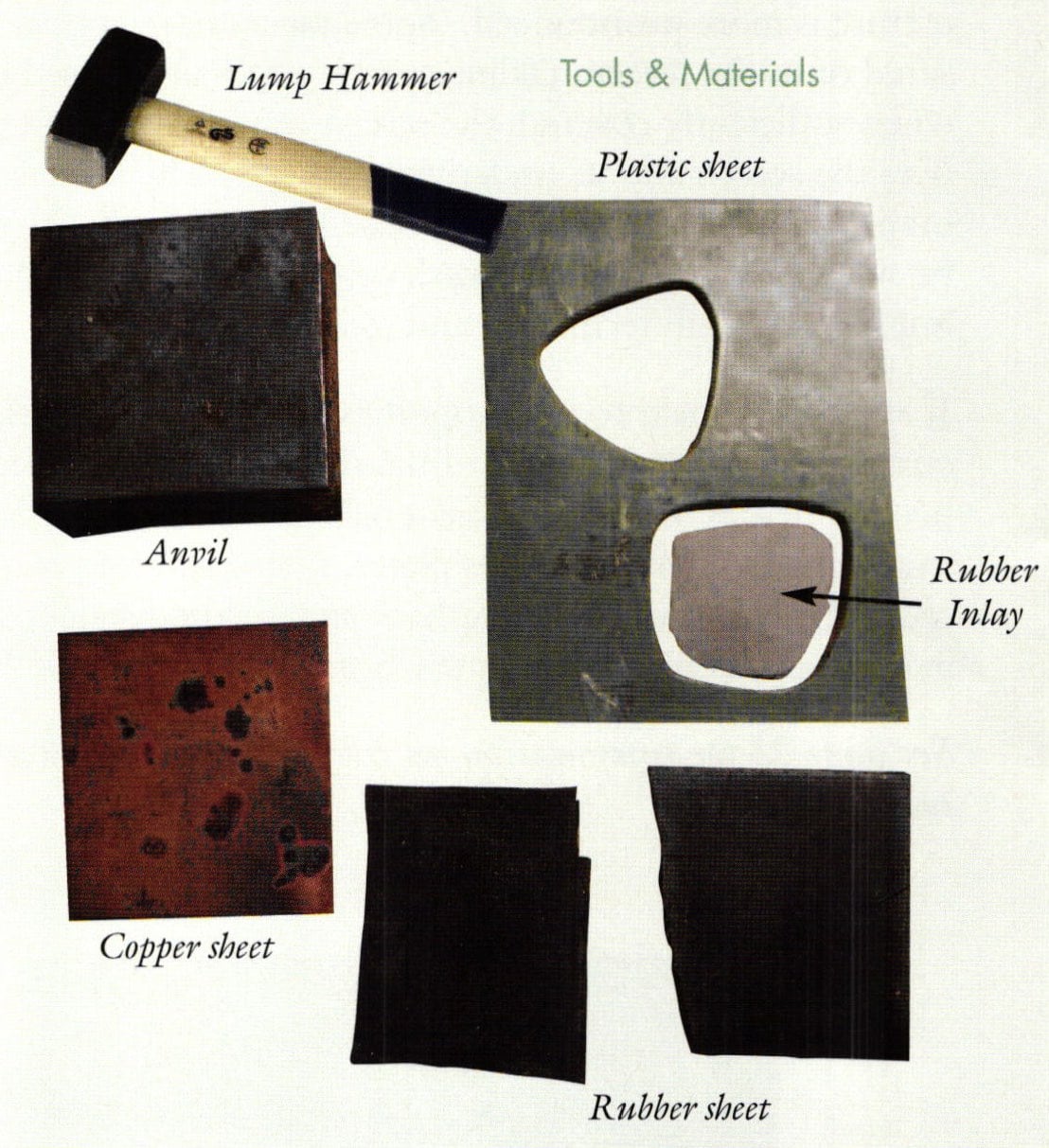

Tools you need

- Lump hammer I-2 kg (2-4 pounds) with a rubber cap or a heavy rubber hammer

- Jewelers saw with coarse and fine saw blades.

- Metal block about 8 x 8 cm, like a bench anvil, or a thick hardwood block. The anvil or the wooden block should be only l-2 cm larger, than the form you want to dome. If the block is too large, you lose a lot of the power of the hammer stroke.

Materials you need

- Plastic sheet not too brittle but a bit elastic, about 5-8 mm thick (do not use Acrylic, it is too brittle)

- Rubber mats, about 5 mm thick, without any inlay, no textile, no wire netting, hardness about 40 shore (measures the hardness of the rubber.)

Procedure

- Sketch the form you want to dome onto the plastic sheet and cut it with a jewelers saw with a coarse saw blade.

- Cut the metal sheet so that it is about 10 mm larger than the form.

- Anneal the metal sheet and let it cool.

- "Sandwich" the items on a solid surface, I used the floor of my workshop in this order: plastic sheet I metal sheet I rubber sheet I anvil. Make sure the metal is larger than the form

- Put a piece of the rubber sheet at the top of the "Sandwich" and then the bench anvil.

- With one forceful strike hit the anvil hard exactly at the top of the anvil. If the strike was hard enough, the metal sheet should dome about 5 mm. If not, repeat steps 3-6.

- For enamel or jewelry work, a dome of about 5 mm should be enough. To heighten the dome:

- Anneal the domed piece.

- Make an inlay of the rubber sheet. It should be a bit smaller than the "doming cutout."

- Lay the cutout inside the dome, then lay the rubber sheet down, placing the anvil on top. With the lump hammer strike the anvil hard. If the doming is higher than one plastic sheet thickness, make a cutout of another plastic sheet a bit larger than the cutout of the form. Lay that with the cutout under the plastic sheet with the form cutout.

Outside Dome Inside Dome

- With the jewelers saw cut saw along the outline of the dome. The domed piece is ready for enameling.

Advantages and Disadvantages of the Method

Advantages:

- Few tools needed

- Rapid and accurate production of curves with an irregular outline

Disadvantages:

- There is more waste because the metal sheet needs to be about I cm larger than the domed form.

Note: If you need to make many of the same forms, it is advisable to make a more stable and longer lasting shape. I glued a piece 1.5 mm thick rigid aluminum plate on a 16 mm particle board. Out of this sandwich, I sawed out the forms.

You assume all responsibility and risk for the use of the safety resources available on or through this web page. The International Gem Society LLC does not assume any liability for the materials, information and opinions provided on, or available through, this web page. No advice or information provided by this website shall create any warranty. Reliance on such advice, information or the content of this web page is solely at your own risk, including without limitation any safety guidelines, resources or precautions, or any other information related to safety that may be available on or through this web page. The International Gem Society LLC disclaims any liability for injury, death or damages resulting from the use thereof.

The All-In-One Jewelry Making Solution At Your Fingertips

When you join the Ganoksin community, you get the tools you need to take your work to the next level.

Trusted Jewelry Making Information & Techniques

Sign up to receive the latest articles, techniques, and inspirations with our free newsletter.